Welcome to our company...

Sanitary Napkin Machine

Product Details:

- Accuracy High Precision Cutting and Folding

- Frame Type Heavy Duty Mild Steel Frame

- Voltage 220-380 V

- Power Rating 5 kW

- Motor Power 3 HP

- Control System PLC Control

- Machine Type Sanitary Napkin Production Line

- Click to View more

X

Sanitary Napkin Machine Price And Quantity

- 1 , , Set

Sanitary Napkin Machine Product Specifications

- 1500-2200 kg

- 220-380 V

- Hydraulic / Pneumatic (customizable as per model)

- 3 HP

- 5 kW

- 5C 40C

- Powder Coated

- PLC Control

- Sanitary Napkin Production Line

- High Precision Cutting and Folding

- Approx. 3500 x 1200 x 2000 mm

- Blue & Silver / Custom

- Heavy Duty Mild Steel Frame

- SNM-101

- PLC Connect, Human Interface Panel

- Sanitary Napkin Making Machine

- Manufacturing sanitary napkins and pads

- Automatic Lubrication

- Non-woven & PE Film

- 60-100 pads per minute

- 4-8 kW (depends on configuration)

- Servo Motor Drive

- High Automation, Low Maintenance, User Friendly Interface

- 50-60 Hz

- Air Cooling

- < 70 dB

- Automatic / Manual

- Electric

- Semi-automatic / Fully automatic

Sanitary Napkin Machine Trade Information

- Xiamen port

- Cash Against Delivery (CAD), Letter of Credit (L/C), Delivery Point (DP)

- 20 , , Set Per Year

- 6-8 Months

- All India

Product Description

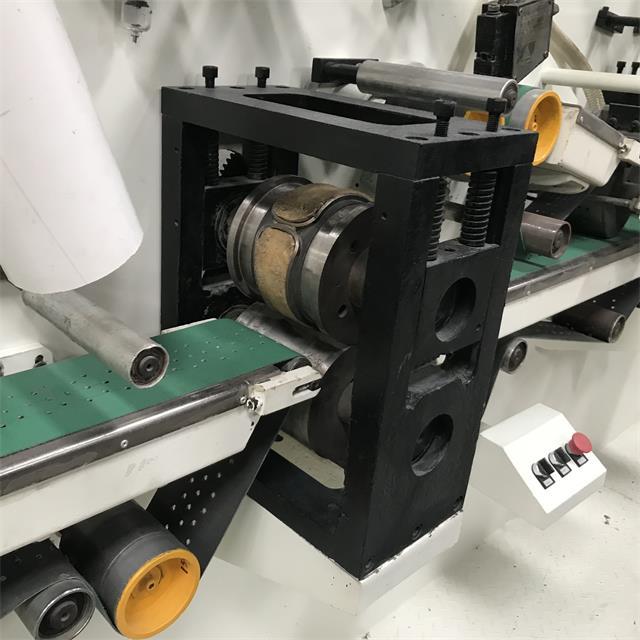

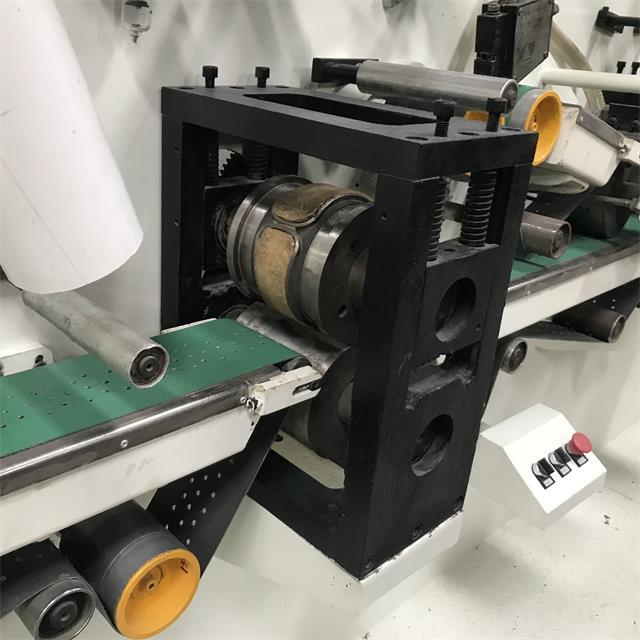

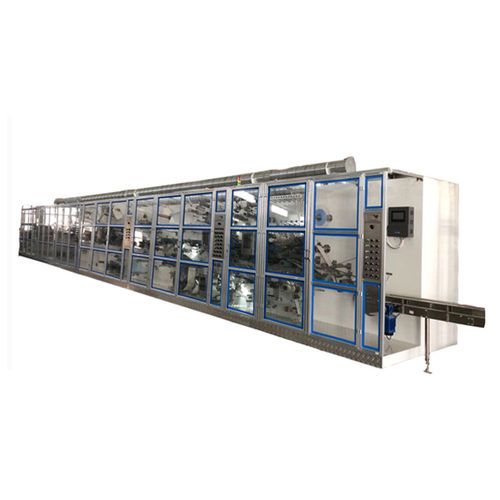

Integrated with powerful main engine, high speed crusher, glue applicator and waist collector, this high quality Sanitary Napkin Machine is offered by us. This machine is widely used for manufacturing sanitary napkin, baby & adult diaper and many such products. It has robust construction of 20m X 3.5m X 3.5m dimension and operate on power supply of 380V 50Hz. The offered product is designed and manufactured by our skilled professionals using latests technology and it can produce 700 pads in a single minute. Owing to these features, Sanitary Napkin Machine is highly popular in domestic as well as international markets.

- Designed Speed ;700pcs/min

- Stable Production Speed :650pcs/min

- Product Weight Deviation :±5%

- Passing Rate :>=98%

- Operating Rate: >=85%

- Power Supply: 380V 50Hz

- Electrical Supply :380V ±5%, 50Hz Three-phase four-wire + ground wire

- Power Installed :About 220KW (Not included hot melt glue machine)

- Supply Pressure :0.6-0.8Mpa

- Machine Sizes: 20m*3.5m*3.5m( just for reference)

- Main Engine Sizes; 25m*7m*5m ( just for reference)

- Machine Color :Customize

Versatile and Customizable Production

Designed to accommodate a wide range of napkin sizes and adjustable thickness, the SNM-101 meets diverse market needs. With compression types including both heat and pressure, as well as customizable edge sealing options, the machine offers flexibility for manufacturers. Changeover between product sizes or settings takes less than 20 minutes, ensuring smooth operations.

Efficient and User-friendly Operation

This sanitary napkin production line supports manual or automatic pad packing, low noise levels, and energy-efficient performance. Its heavy-duty frame, servo motor drive, and air cooling system guarantee durability. The PLC control system with an intuitive interface allows for precise adjustments and fault detection, enhancing operational safety and simplicity.

High Output and Low Maintenance

With the capacity to produce 60-100 pads per minute, the SNM-101 maximizes production while keeping maintenance low. Automatic lubrication and surface powder coating contribute to longevity, while the design mandates only 1-2 operators. The machines robust construction is suitable for continuous operation in varied environments.

FAQs of Sanitary Napkin Machine:

Q: How does the SNM-101 ensure high precision in sanitary napkin production?

A: The SNM-101 utilizes a PLC control system and servo motor drive, along with high-speed steel cutting blades and precision folding technology, to achieve high accuracy in cutting and folding each pad, minimizing material wastage.Q: What are the raw materials compatible with this machine?

A: This machine is designed to process non-woven fabric, pulp, SAP, PE back sheet, and PE film, enabling the production of high-quality sanitary napkins with customizable thickness and absorption features.Q: When should I switch between manual and automatic pad packing?

A: You may choose manual packing for lower production volumes or frequent product variation. For higher volumes and consistent product types, automatic packing optimizes efficiency and reduces operator intervention.Q: Where can this machine be installed, and what are its space requirements?

A: The SNM-101 is suitable for installation in medium to large manufacturing facilities. It requires a space of approximately 3500 x 1200 x 2000 mm and can operate in environments with temperatures ranging from 5C to 40C.Q: What process features contribute to low maintenance and downtime?

A: Key features such as automatic lubrication, robust powder-coated frame, automatic fault detection system, and high-quality modular components ensure the machine remains low maintenance and that potential issues are quickly identified and resolved.Q: How is operator safety addressed during machine operation?

A: Operator safety is prioritized through an automatic fault detection system that provides alerts, a user-friendly interface for secure controls, and design elements that reduce direct contact with moving parts during operation or maintenance.Q: What are the key benefits of using this sanitary napkin machine?

A: The SNM-101 offers high automation, user-friendly operation, customizable output, low energy consumption, and the ability to produce consistent, high-quality napkins at rapid speedsmaking it an excellent investment for manufacturers and suppliers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sanitary Napkin Machine' category

|

WELLDONE (CHINA) INDUSTRY LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |