Welcome to our company...

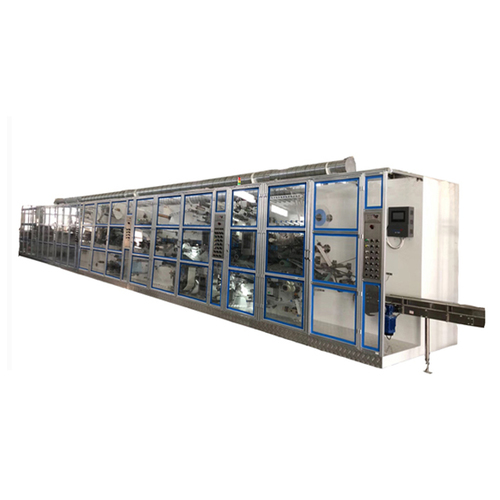

Fully Automatic Sanitary Napkin Production Line

200,000-500,000 USD ($)/Set

Product Details:

- Machine Type Napkin Making Machine

- Operating Temperature 5C to 40C

- Model No FASNP-1200

- Cooling System Water/Air Cooled

- Connectivity Options Ethernet/USB/Remote Monitoring

- Power Rating 120 kW

- Noise Level <80 dB

- Click to View more

X

Fully Automatic Sanitary Napkin Production Line Price And Quantity

- 200,000-500,000 USD ($)/Set

- 1 set Set

Fully Automatic Sanitary Napkin Production Line Product Specifications

- FASNP-1200

- Water/Air Cooled

- 5C to 40C

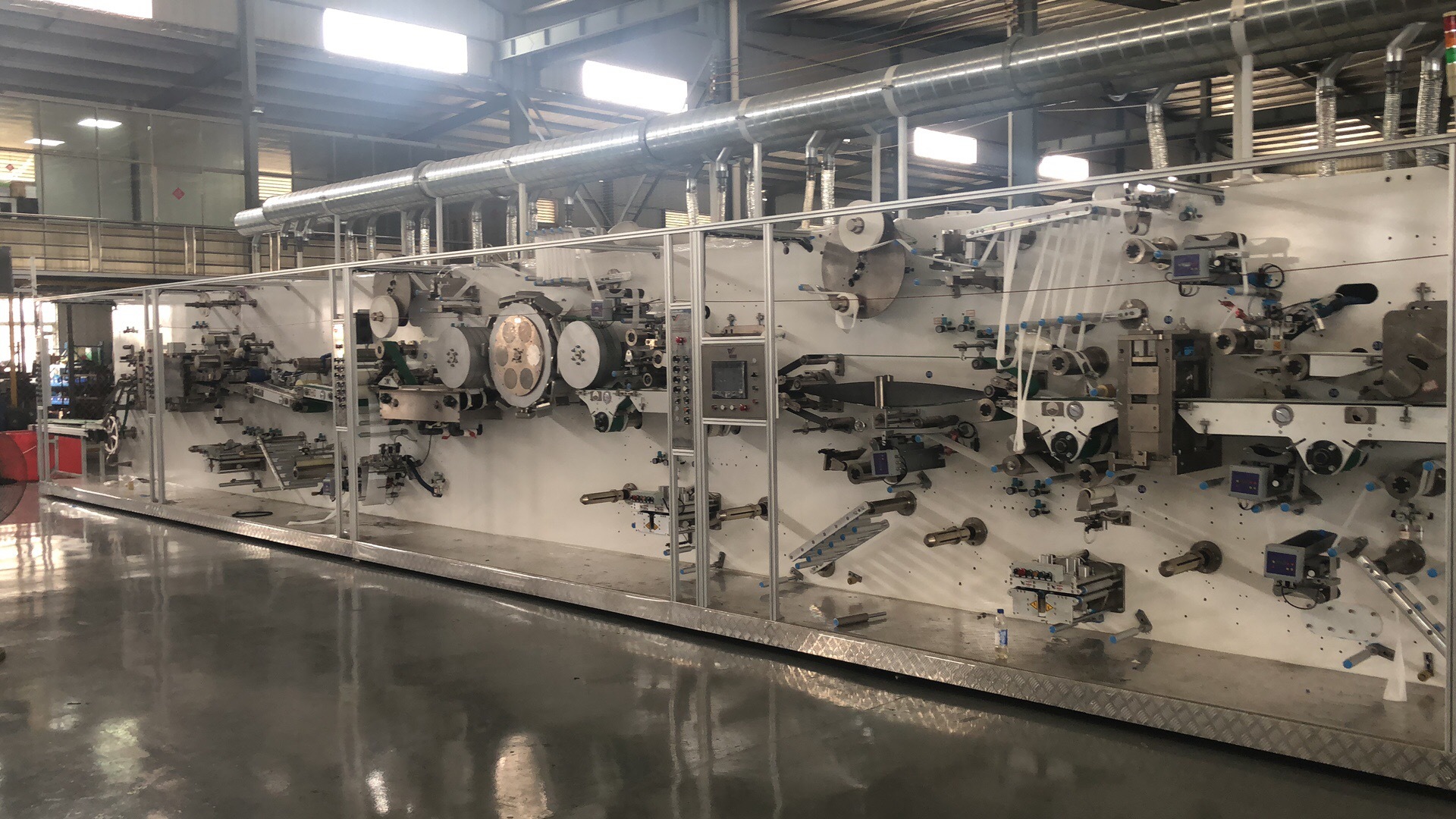

- Approx. 24,000 x 2,500 x 3,000 mm

- Sanitary Napkin Production Line

- Napkin Making Machine

- Fully Automatic Servo Control

- Integrated Servo Motors

- 5-8 bar (pneumatic components)

- Heavy Duty Steel Frame

- ~120 kW

- Ethernet/USB/Remote Monitoring

- 120 kW

- <80 dB

- High Precision Cutting and Placement

- Automatic Lubrication

- 380V/ 415V Three Phase

- Industrial Grey/Customization Available

- Electric

- Powder Coated/ Painted

- Servo-driven, Modular Design, Remote Diagnostics

- 800-1200 pcs/min

- Automatic

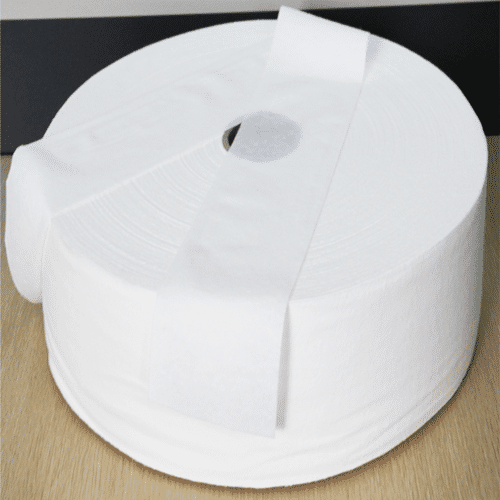

- Non-woven, PE Film

- 50/60 Hz

- PLC with Touch Screen HMI

- Feminine Hygiene Products Manufacturing

- 28,000 Kg

- Full Servo Drive

Fully Automatic Sanitary Napkin Production Line Trade Information

- Xiamen Port

- Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 10 Set Per Year

- 120 Days

- Yes

- Free samples are available

- Antirust Oil & PE Film Cover & Seaworthy Wooden Box. 5*40HQ containers for machines making disposable Adult diaper

- CE certification ISO9001

Product Description

Fully Automatic Sanitary Napkin Production Line is widely used for producing baby & adult diapers, sanitary napkins, maternity pads, under-pads and many such products. It is a heavy duty machine attached powerful motors, waste material collector etc and has the capability to manufacture around 700 pads per minute. This machine has PE film cover, which provides it oil resistant and rust proof nature.

Quick Details

- Product Type: Sanitary Napkin Machine

- Processing Type: Laminating Machine

- Power(W): 250

- After-sales Service Provided: Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

- Warranty: 1 Year

- Applicable Industries: Manufacturing Plant, paper production making machine

- Condition: New

- Place of Origin: Fujian, China (Mainland)

- Brand Name: DNW Machinery

- Voltage: 220/380

- Dimension(L*W*H):

- 28mX5.5mX3.5m

- Weight: 40Tons

- Certification: CE

- Production Capacity: 90-240 million pieces/year

- Name: Semi-servo Full Automatic Straight Sanitary Napkin Machine

- Color: Customized Color

- Finished Products: Sanitary Pad with Straight Package

- Raw Material: Wood Pulp/PE Film/Nonwoven/SAP

- Application: Sanitary Napkin Producing

- Waste Rate: Less Than 2%

- Manufacture Time: 120 Days average

- Machine Grade: Semi servo

- Operators: 8-10

Highly Automated and Precise Operation

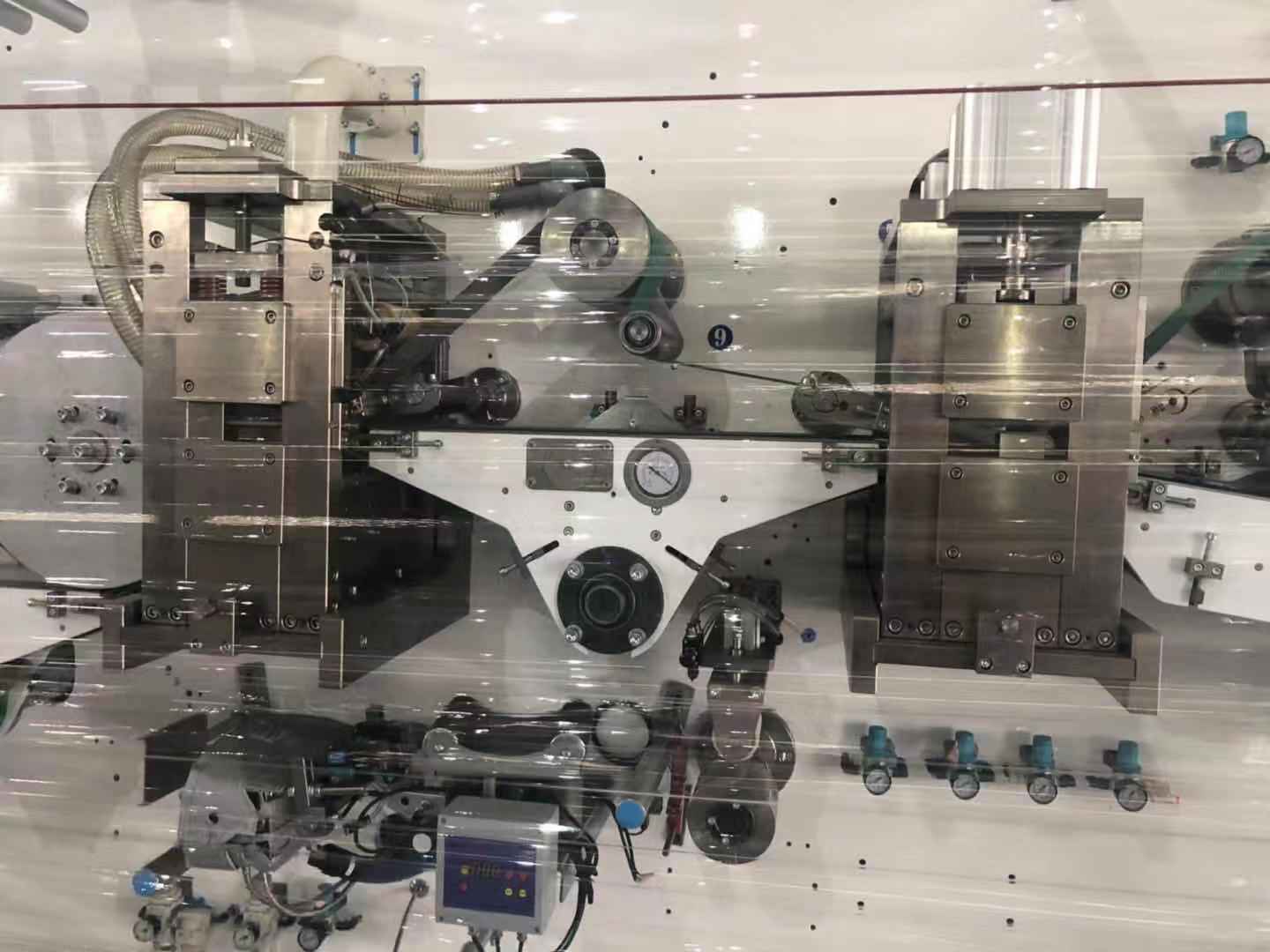

Engineered for full automation, the production line uses servo motors, PLC control systems, and vision-based defect detection to maintain uncompromised quality. Operators benefit from a color HMI with multi-language support and remote monitoring capabilities, streamlining operations while ensuring product consistency at high speeds.

Comprehensive Safety and Maintenance Features

Safety is prioritized through complete guarding, emergency stops, and automatic lubrication. The system is robustly constructed with a heavy-duty steel frame and powder-coated surface for durability. Onsite installation assistance is provided to support seamless setup and operation, while modular design allows for easy maintenance and upgrades.

Optimized Production, Minimal Downtime

Fully automatic conveying and unwinding systems ensure steady raw material supply, while automatic trim removal maintains cleanliness. The line offers quick changeovers (under 60 minutes), automatic tension control, and reliable temperature management in hot-melt applicators. Inline packing (optional) ensures ready-to-market products without additional handling.

FAQs of Fully Automatic Sanitary Napkin Production Line:

Q: How does the automatic defect detection system enhance product quality?

A: The line integrates a vision system for auto defect detection, which monitors each sanitary napkin for flaws during production. This immediate feedback enables rapid removal of defective products, ensuring each item meets stringent quality standards without manual inspection.Q: What materials can be processed by the sanitary napkin machine?

A: This machine efficiently processes non-woven material and PE film, which are commonly used in feminine hygiene products. The multiple automatic unwinders guarantee smooth feeding and tension control for these materials throughout the production process.Q: When is installation assistance available for this production line?

A: Installation assistance is available onsite upon delivery of the machine. Expert technicians will guide you through setup, commissioning, and initial training to ensure optimal operation and safety compliance from the start.Q: Where can remote diagnostics and monitoring be accessed?

A: The production line features Ethernet/USB connectivity as well as remote monitoring capabilities. This allows operators and service teams to access diagnostics, make adjustments, and perform troubleshooting from local or remote locations, improving uptime and efficiency.Q: What process steps are involved in producing sanitary napkins using this machine?

A: Beginning with automatic raw material feeding and unwinding, the process includes precision embossing with pneumatic or servo units, defect detection, high-speed cutting and placement, automatic trim removal, and optional inline packing. Each step is fully automated to maintain quality at high production rates.Q: How is changeover managed, and how long does it take?

A: Thanks to its modular, servo-driven design, the machine allows for rapid changeover between napkin sizes or styles. Changeover is completed in less than 60 minutes, minimizing downtime and maximizing production flexibility for various product lines.Q: What are the primary benefits of using this fully automatic production line?

A: Key benefits include high-speed, high-accuracy production, enhanced safety features, efficient material usage, reduced manual labor, quick changeover capability, and advanced connectivity for remote operation and diagnostics, streamlining the manufacturing process for feminine hygiene products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sanitary Napkin Machine' category

|

WELLDONE (CHINA) INDUSTRY LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |